Meet the Total Solution

We've got you. From initial build outs to SKU production, our iconic brands make up the best equipment and service professionals on the planet and we're ready to help you improve your performance.

Hear From Our Customers

"The flower grown in the Agrify VFUs Is the best flower I have seen all year."

MSO purchasing agent and WhiteCloud Botanicals customer

"There were technical factors that led us to Agrify, plus they worked with us, they were really good to work with and they were incredibly knowledgeable."

Kevin Ferdowisan, Easy Street Extracts

Updates from Nevada Holistic Medicine

up to 6x

crop yield per square foot vs. traditional grows

up to 29%

more cannabinoid potency over traditional cultivation

up to 98+%

continuous utilization of infrastructure achieved with our software

Sign up for Agrify updates for news on our latest innovations.

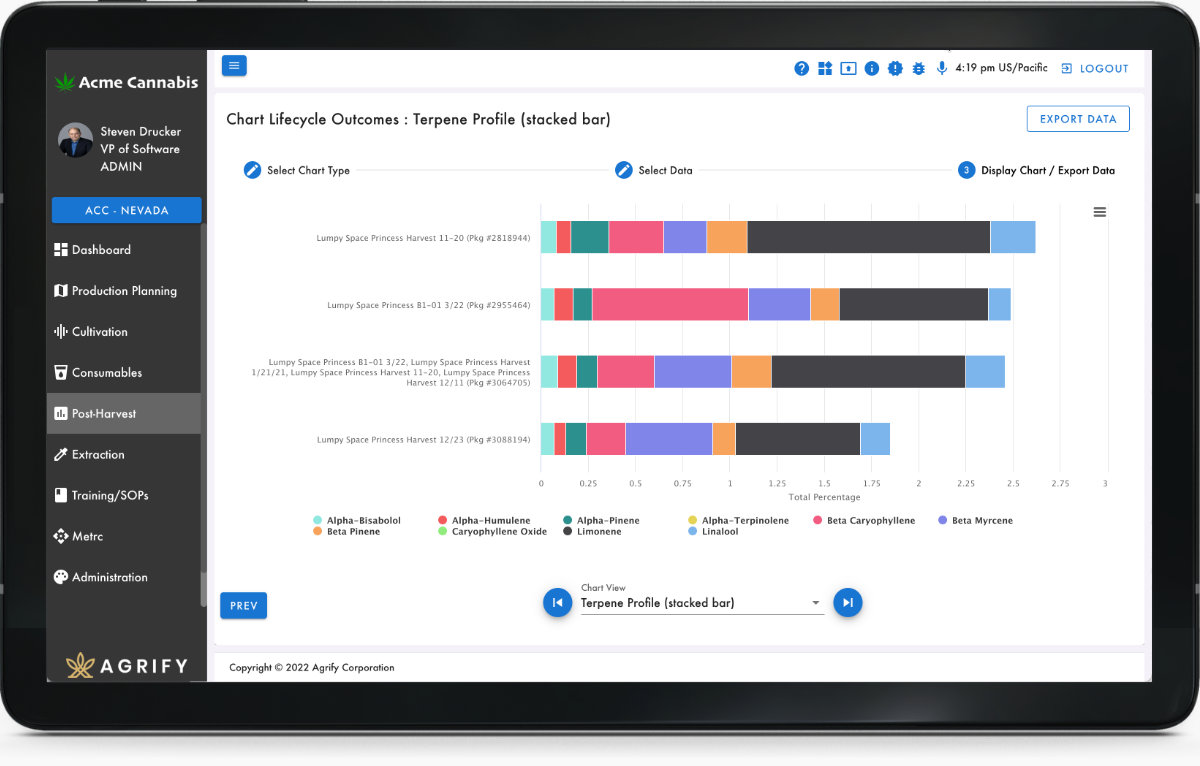

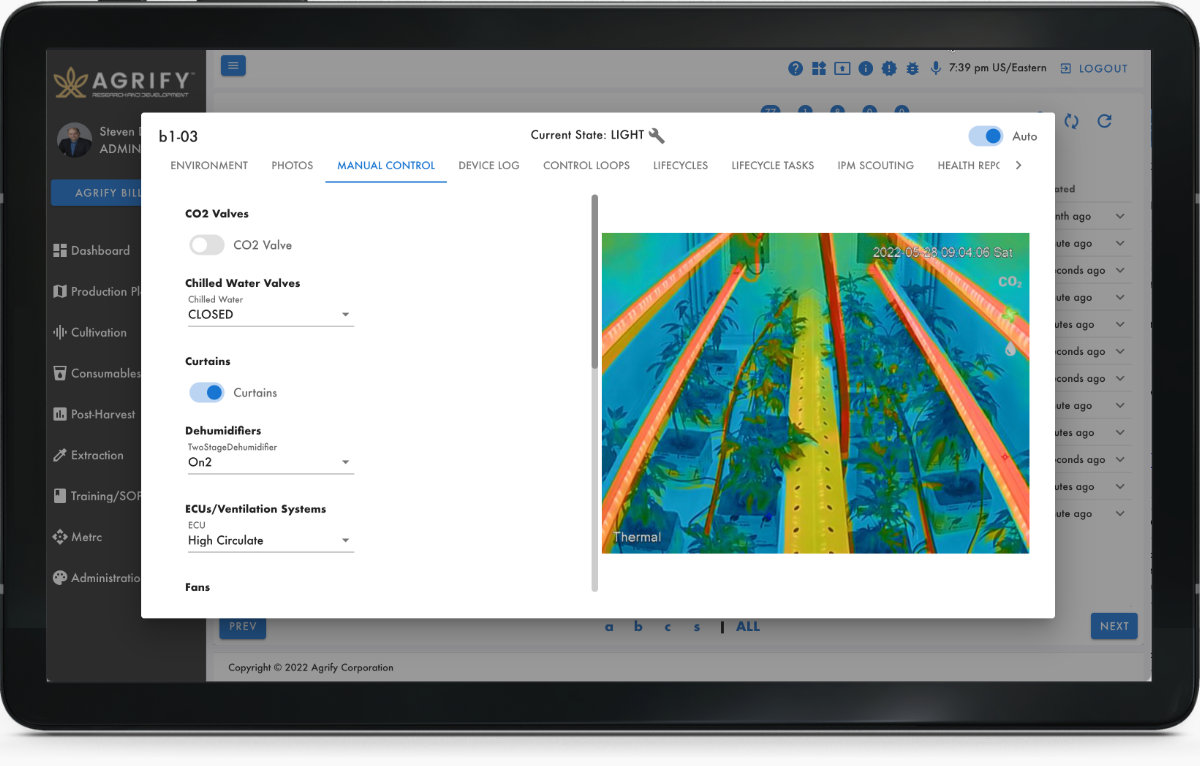

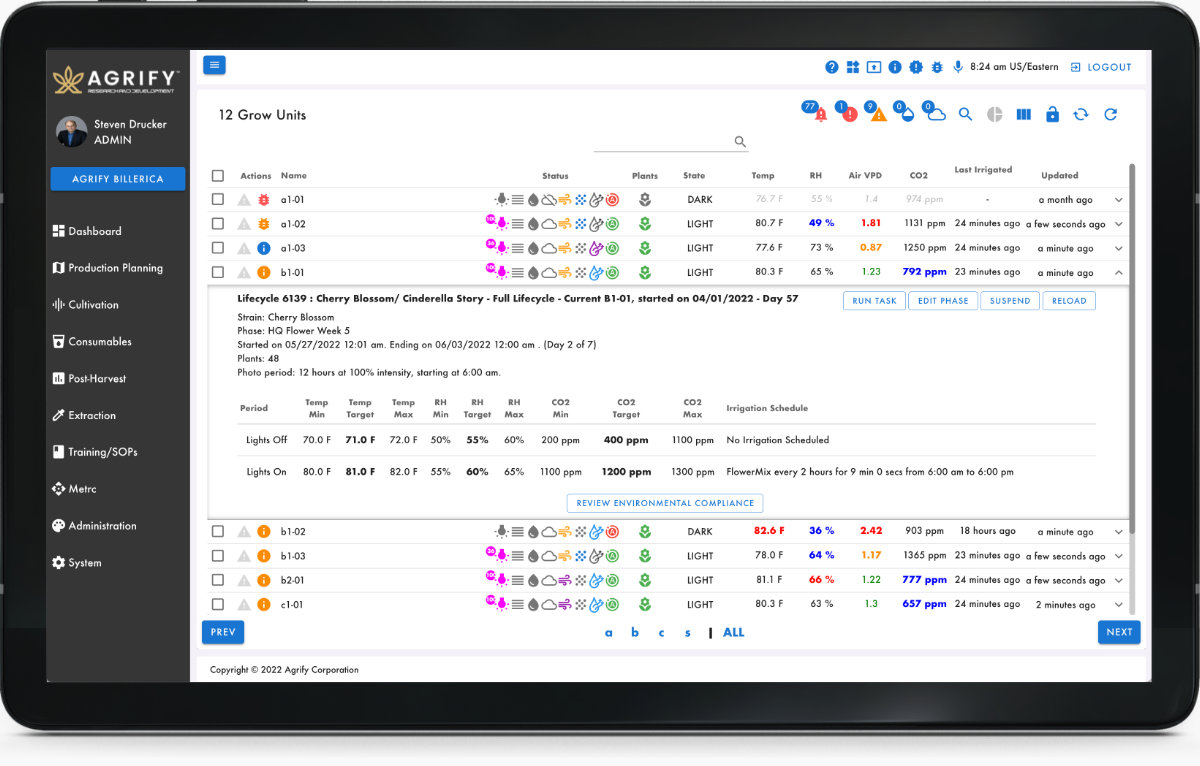

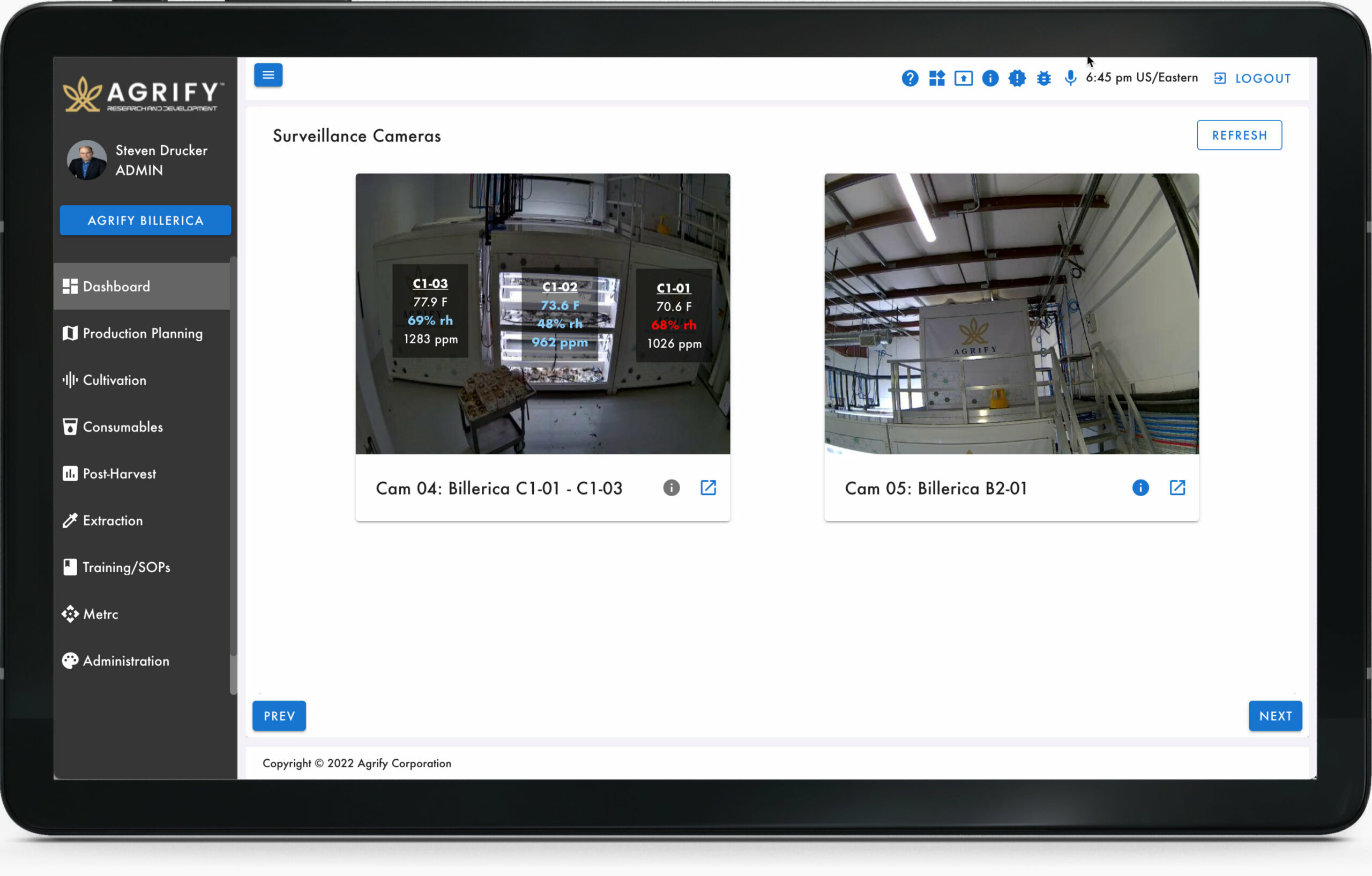

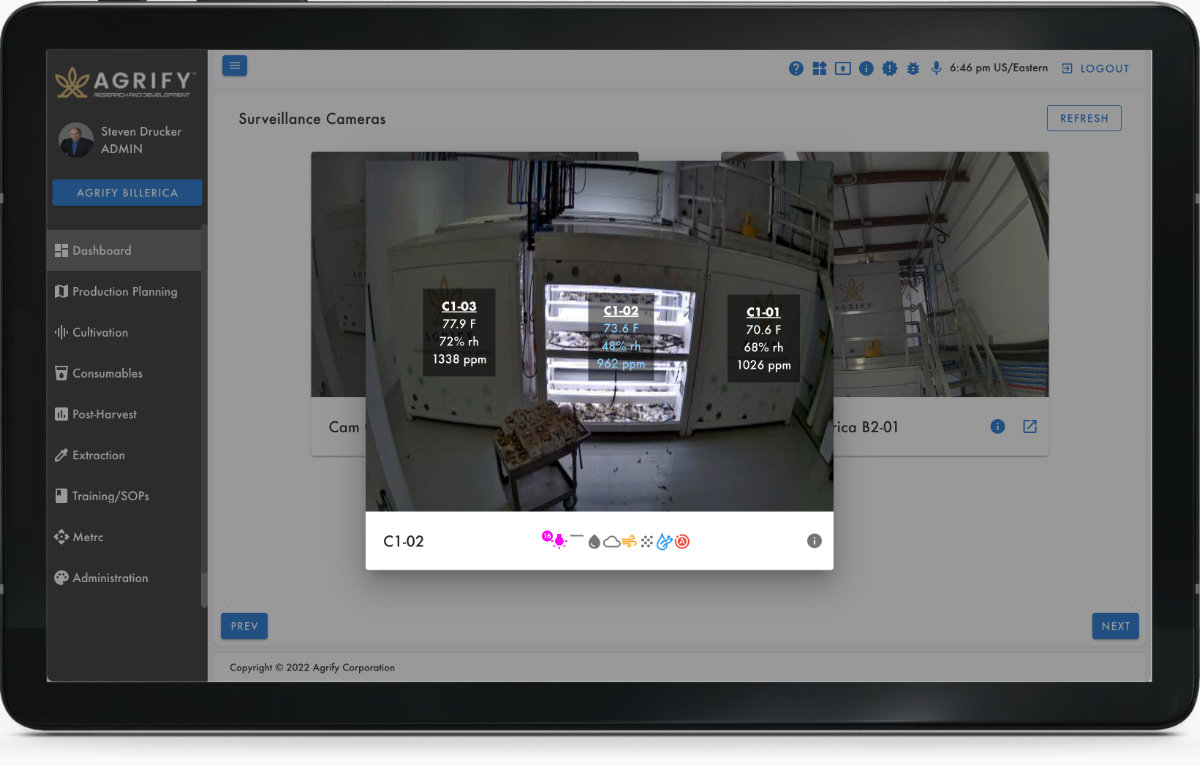

Insights at your fingertips.

The data you need to deliver.

Agrify Insights cultivation software delivers a fully controlled, data-driven grow environment. From OPEX calculators to cameras, data & grow plans to scheduling.

Agrify Insights provides updates and nuanced controls from anywhere with a cell signal. For the control and peace of mind you need to optimize your grow.

Training, Consulting, & Installation Services

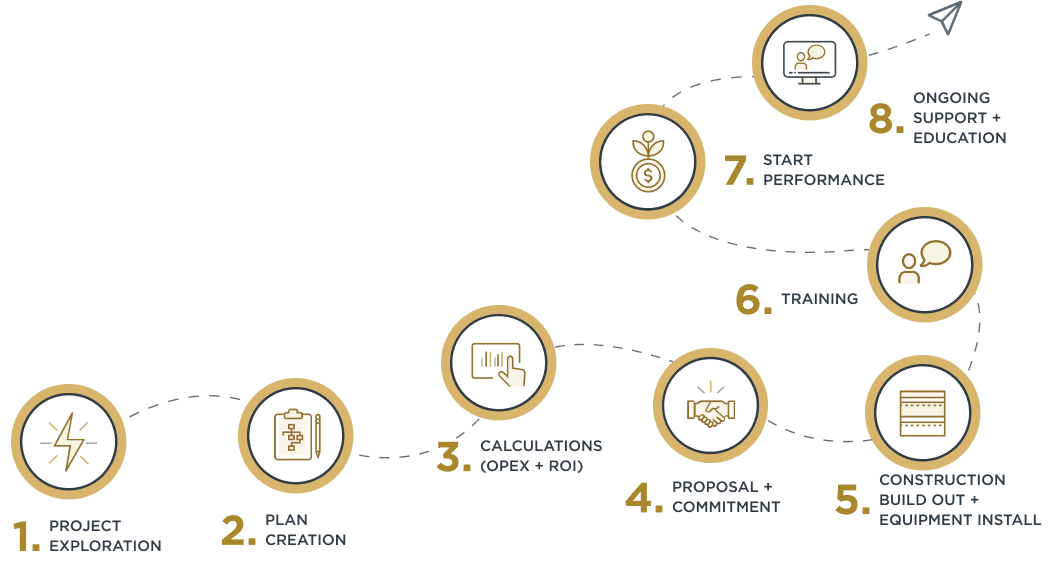

Fast Track Your Success

You've worked tirelessly to get to this point and our product experts are here to fast-track your team on the path to success. Experts from our iconic family of brands are dedicated to empowering your team with systems training and installation that will help you exceed production goals while producing world-class products.

Curate your cannabis cultivation & extraction training package from our vast options to level up your operation and expedite your success with world-class consulting that will save your business time, capital, and resources with customizable solutions to meet your end goals.

About Agrify

Our Story and Our mission

Agrify is the most innovative provider of advanced cultivation and extraction solutions in the cannabis industry, bringing science, chemistry, technology, and data to the forefront.

Our comprehensive grow solutions have been developed with one mission in mind: to assist our partners in achieving the highest quality, consistency, and yield-at the lowest possible cost.

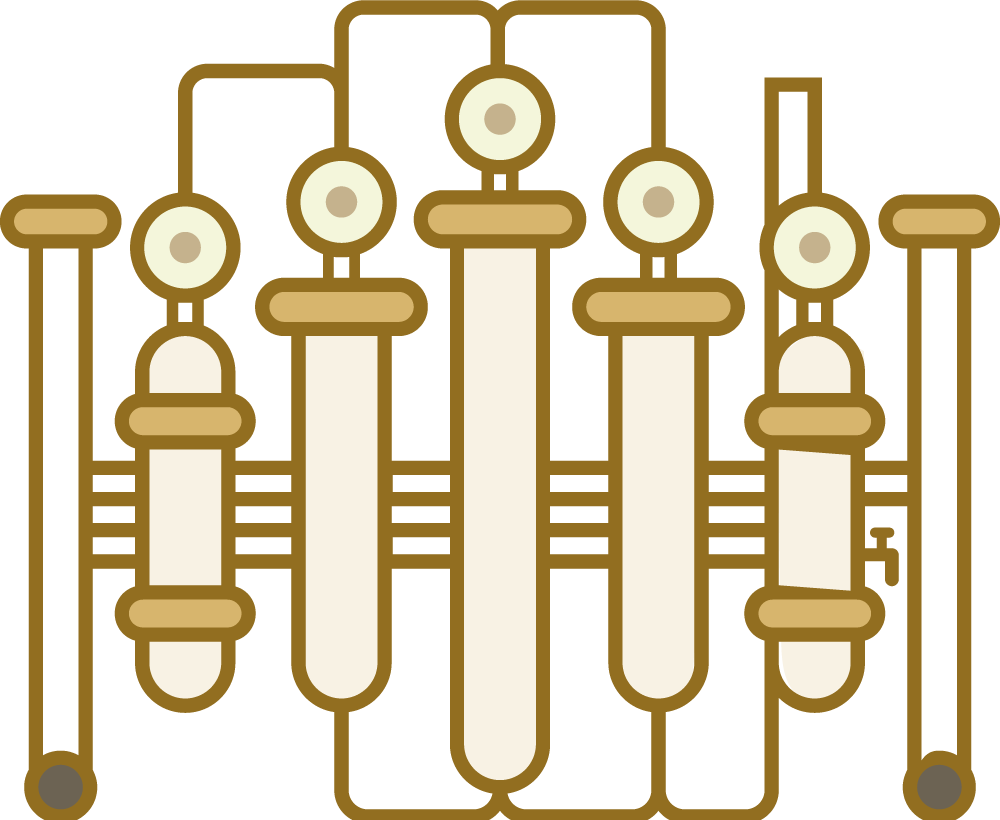

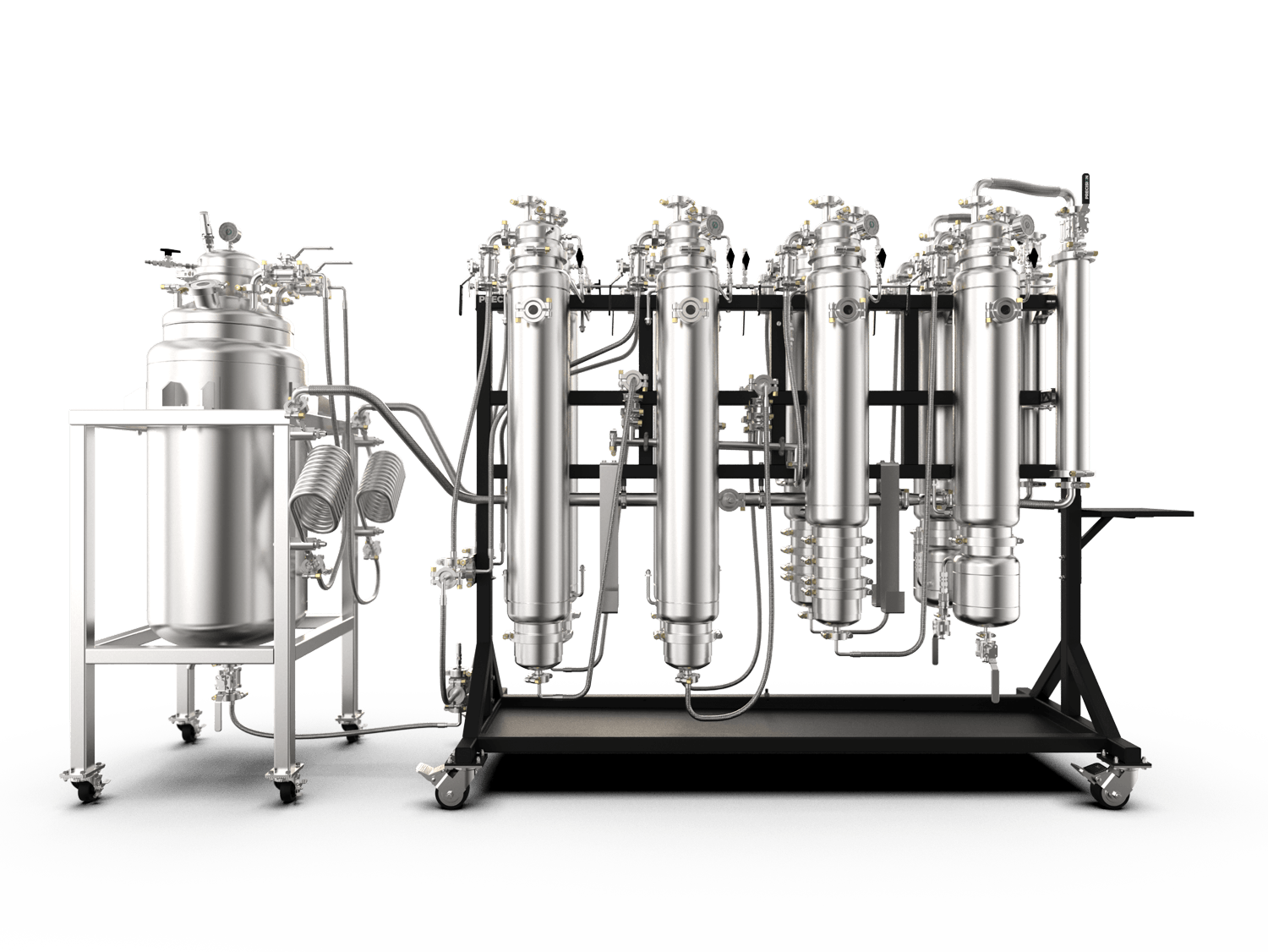

Industry-leading hydrocarbon and solventless extraction equipment as well as distillation equipment and vacuum ovens provide everything needed to take your business to the next level using Agrify Extraction solutions.

From total turnkey solutions to individual products, Agrify is the most innovative provider of advanced cultivation and extraction solutions in the cannabis industry.