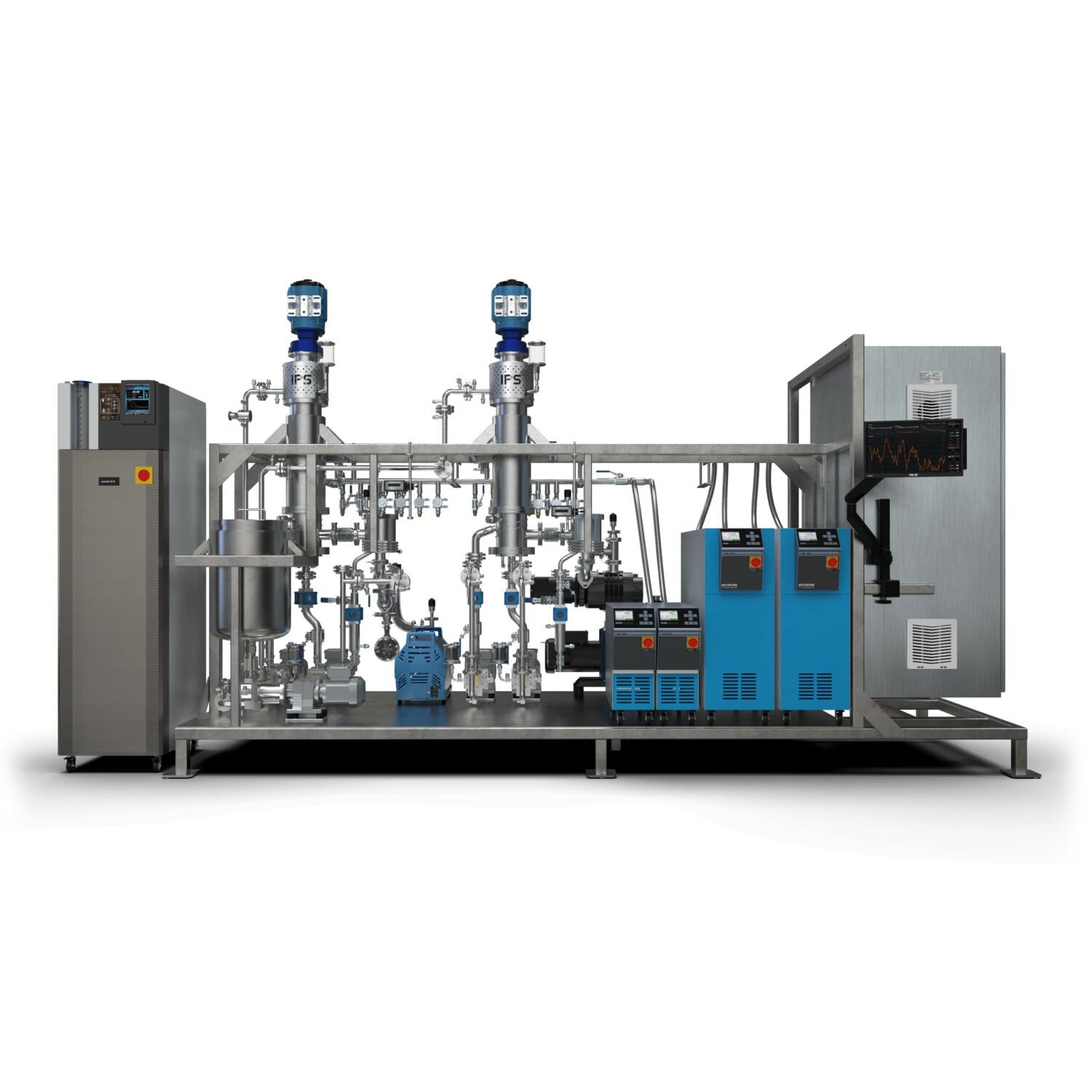

- Completely jacketed stainless steel process piping

- Good Manufacturing Practices (GMP) forward design

- Inline sight glasses

- Jacketed feed tank, 8-Gallon

- Manual isolation valves

- Material contact surfaces: 316L stainless steel

- Coriolis Flow Meters for reliable, high-viscosity fluid flow monitoring (replacing geared flow meters) with custom cast thermal jackets.

- Digital pressure transmitters for gear pumps (replacing analog gauges)

- Standardized insulated cold trap jumper hoses and insulated external cold trap coils

- Fully welded hot oil lines

- Factory Acceptance Testing (FAT) standard

- Various Feed Tank options (3-Stage only)

- Various Human-Machine Interface (HMI) options

- Various vacuum system options

System Advantages Summary

Single Stage Units:

Utilizing a single stage distillation unit requires multiple passes through the unit to achieve sellable product. Each pass through the machine requires different operational parameters including temperature, pressure, and speed. The dual-pump manifold gives users the ability to run volatile and/or heads stripping passes with a dry vacuum pump coupled with a pressure controller. This provides the ability to set precise pressures alongside temperatures to make stripping passes optimal and most effective.

After the feed product has been thoroughly stripped and prepped for final, heavy compound distillation, users can clean the system and then utilize the rotary vane pump assembly to reach high vacuum levels effectively without disassembly of the unit. This greatly improves the operational simplicity of the units as well as flexibility to perform various distillation types within one machine.

2-Stage Advantage:

Having multiple stages reduces the need for multiple passes when material is properly prepared for the system by utilizing two (2) stages of short path distillation; thus, continuously collecting two (2) distillate fractions and one (1) residue fraction. The first stage is run at higher pressure (low to medium vacuum) and lower temperature to gently or aggressively remove low to medium boiling point compounds. The second stage is run at high vacuum and higher temperature to achieve proper separation of compounds.

Speed & Pass Data

| Speed & Pass Data | CannaBeast® 20 (1-stage) |

CannaBeast® 60 (1-stage) |

CannaBeast® 20 (2-stage) |

CannaBeast® 60 (2-stage) |

CannaBeast® 60 (3-stage) |

| Min Feed Flow Rate | 5 LPH | 10 LPH | 5 LPH | 10 LPH | 10 LPH |

| Max Feed Flow Rate | 20 LPH | 60 LPH | 20 LPH | 60 LPH | 60 LPH |

| Avg. Feed Flow Rate | 15 LPH | 40 LPH | 15 LPH | 40 LPH | 40 LPH |

| Minimum Passes | 2 | 2 | 1 | 1 | 1 |

| Output Fractions | 2 | 2 | 3 | 3 | 4 |

Space and Delivery Requirements

- Units should be at least 2′ from any wall

- Ceilings must be high enough to accommodate for wiper basket removal

- Forklift rated for a minimum of 5000lbs, must have extended forks

- Ensure machinery location doorway is large enough for footprint listed below

| Dimensions | CannaBeast® 20 (1-stage) |

CannaBeast® 60 (1-stage) |

CannaBeast® 20 (2-stage) |

CannaBeast® 60 (2-stage) |

CannaBeast® 60 (3-stage) |

| Width (in.) | 123.5″ | 123.5″ | 147.5″ | 147.5″ | 183.5″ |

| Depth (in.) | 52 (PLC 64) | 64 | 52 (PLC 64) | 64 | 64 |

| Base HMI Height | 92″ | 122″ | 92″ | 122″ | 122″ |

| PLC Standard Height | 92″ | 122″ | 92″ | 122″ | 122″ |

| PLC Auto Height | 132″ | 157″ | 132″ | 157″ | 157″ |

| Motor + Basket Clearance | 36″ | 48″ | 36″ | 48″ | 48″ |

Electrical Requirements

- Requires a sub-panel with a main disconnect break on panel, sub-panel will have direct connection via conduit into the control panel of the skid

- Skid has self-contained electrical connections for all utilities on control panel, with the exception of the cold trap chiller

- Cold trap chillers are located off of skid and are recommended to have their own electrical connection to avoid distance to connection issues

- Electrical Specifications for cold trap chillers:

- Huber CC-902: 208V 2 Ph, 60 Hz, 14.5 Amps

- Huber Unistat 815: 208V 3 Ph, 60 Hz, 21.5 Amps

- Huber Unistat 815: 460V 3 Ph, 60 Hz, 11.0 Amps

- Requires Professional Electrician to connect Skid to Sub-panel

| Dimensions | CannaBeast® 20 (1-stage) |

CannaBeast® 60 (1-stage) |

CannaBeast® 20 (2-stage) |

CannaBeast® 60 (2-stage) |

CannaBeast® 60 (3-stage) |

| Voltage | 208Y | 208Y | 208Y | 208Y** | 208Y** |

| 50% Amps | 60 | 75 | 75 | 110 | 125 |

| Max Amps* | 120 | 150 | 150 | 220 | 250 |

| Panel Max* | 150 | 275 | 150 | 300 | 300 |

| Heat Gen @ 50% | 35,000 BTU/Hr | 47,500 BTU/Hr | 47,500 BTU/Hr | 66,500 BTU/Hr | 86,000 BTU/Hr |

| Heat Gen @ 100% | 70,000 BTU/Hr | 95,000 BTU/Hr | 95,000 BTU/Hr | 133,000 BTU/Hr | 172,000 BTU/Hr |

* Max Amps is the maximum amp draw of the system’s utilities; Panel Max is the maximum amperage that the system’s electrical panel can accept.

** Alternative voltage options available upon request.

Precision offers the following on-site product installation and training with experienced extraction technicians:

- Extract Product Engineering

- Distillation Prep

- Distillation Training