Irrigation and fertigation systems are standard technologies used across commercial agriculture. And increasingly, cannabis cultivators are adopting this technology to streamline operations, automate manual processes, and scale profitably.

Automated fertigation systems deliver preformulated nutrients and water to each plant on a set schedule. The business benefits? These systems help cultivators get labor costs under control, replicate perfect harvests, and create consistency.

The Premise Is Simple: Automation Allows Cannabis Cultivation at Scale

Small-scale growers mix nutrients in small batches by hand. Every batch is manually measured, adjusted, mixed, and dosed, all relying on recipes often scratched out on notepads and whiteboards.

But in the commercial space, delivering that much love and hands-on attention to every plant and cultivar in production is impossible.

Indoor and greenhouse cannabis cultivators typically have dozens of strains and thousands of plants in production at once, all in various stages of growth. Therefore, automation of the most manually intensive tasks is the only way to successfully deliver that love and attention while staying profitable.

Automated irrigation and fertigation promises that each plant receives the hydration and nutrients it needs exactly in step with its current growth stage. Furthermore, it does so without the thousands of staff hours that would otherwise be required to prepare and dose each nutrient recipe manually.

What’s the Best Cannabis Fertigation and Irrigation System?

During the facility buildout or retrofit, what do you need to evaluate when it comes to the fertigation and irrigation system?

It is a core aspect of the system, right alongside lighting and HVAC. Considering the substantial upfront investment — which does pay off within the first few harvests — it’s not a decision to take lightly.

Customizable at Scale

Horticultural fertigation systems for cannabis have to handle dozens, if not hundreds, of nutrient recipes, targeting every single cultivar in every week of growth.

What’s more, the system needs to be easy for growers to tweak recipes and expand the database as new strains enter the grow room and new crop steering methodologies come online.

Look at the long term business plan. Assess how many plants, cultivars, schedules, and rooms does the fertigation system need to serve, not only now but for any long-term growth expected within the next five to ten years.

As a foundational hardware component within the operation, it can make financial sense to invest in the future during the initial build-out, rather than having to completely redesign (or replace) the system during the next phase of expansion. So install the hardware now to save on upgrade nightmares in the future.

Real-Time Feedback Loop

Automated fertigation systems are increasingly dynamic. That means they don’t simply formulate and dispense nutrients on a predetermined schedule. Instead, many systems actively communicate with environmental controllers for real-time feedback on what each cultivar or zone requires.

Is your facility employing crop steering or other advanced cultivation techniques that need real-time communication loops between plants and environmental inputs?

The more advanced the system, the more integrated and responsive it becomes with the broader environment. For example, some systems allow for specific zones to send demands to the irrigation/fertigation system based on the cultivar schedule. Then, the system monitors the feedback, including solution electrical conductivity (EC) and pH, to actively adjust as needed.

Data and Analytics

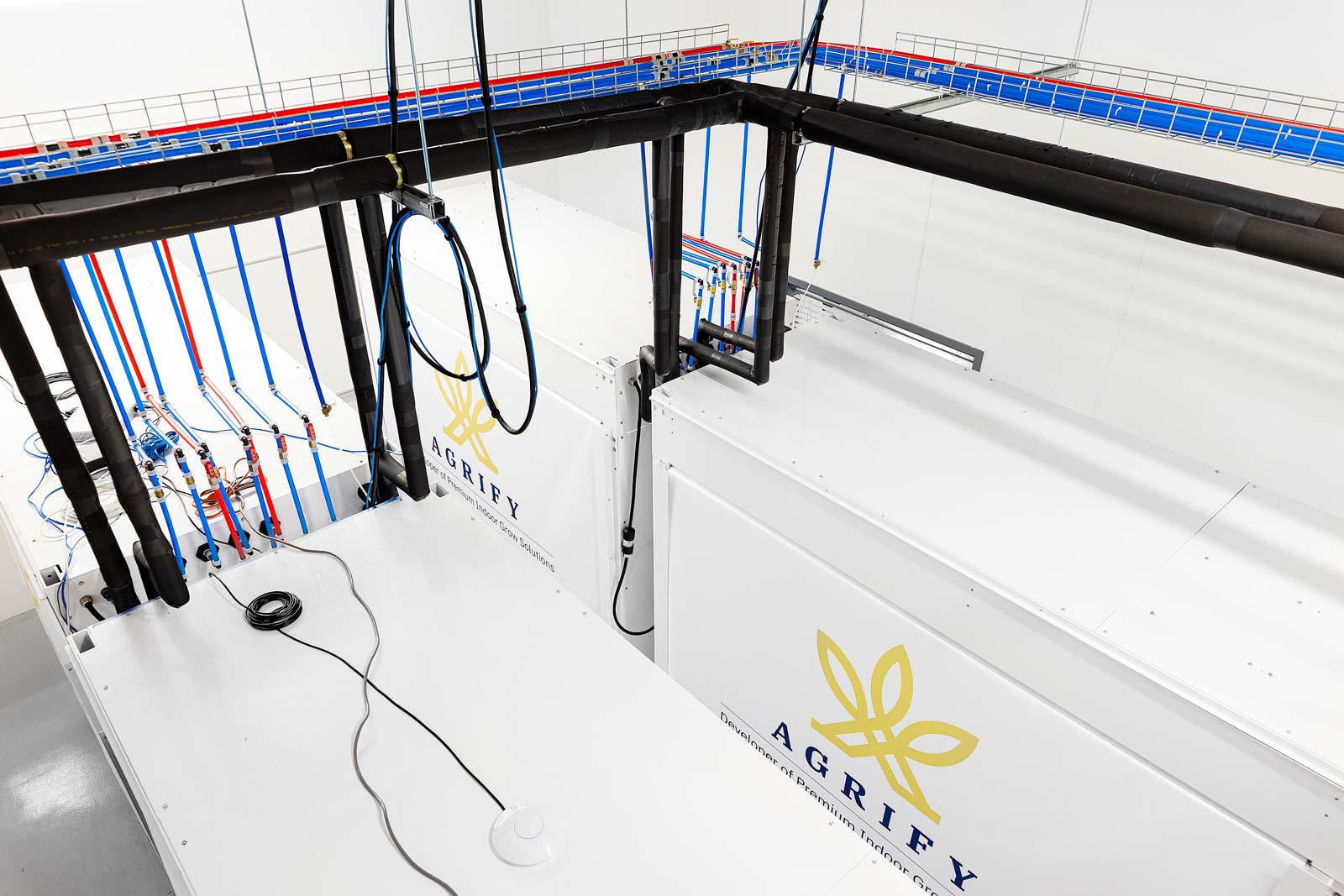

Juggling the data from every single nutrient recipe and schedule across every room and strain is only possible through automation and grow room software. As only one example, each of Agrify’s Vertical Farming Units (VFUs) pulls up to 1.5 million data points annually.

Owners, managers, and growers must parse this data to plan, monitor, and optimize production. Yet, it’s only possible at this scale through robust cultivation software.

As a final consideration, you’ll want to ensure that whatever system you choose for fertigation and irrigation captures real-time and historic crop data. This data needs to be not just readily accessible but also legible to even the non-data analysts on the team.

Whether the system integrates into a grow room controller or comes rolled into an all-in-one grow room solution like Agrify’s VFUs, stakeholders need timely access to easy-to-digest data. Growth is only possible through data-driven decision-making.

Agrify: An All-in-One Cultivation Solution

Agrify ensures that owners and cultivators have the tools they need to grow profitably and at scale. First, vertically stacked compartmentalized growing environments are engineered to provide everything plants need to thrive, including LED grow lights, environmental controls, CO2, and an automated fertigation system.

Then, Agrify Insights, a cloud-based cultivation software, helps facilities grow smarter with precision grow room monitoring and controls backed by data-driven insights.

Find out if this total cultivation solution is for you.